Japan Quality

Clothing

Manufacturers?

We will propose the best way to

meet your needs.

01About Us

Just like the company name, our belief, "Flourishing with harmony" is the circle of each employee = harmony. We believe that the harmony among all employees spreads to our business partners and then throughout society. We are a fashion manufacturer, but not only manufacturing, we will also deliver products that can convey the dreams of each employee and the commitment of the craftsmen.

We intend to further strengthen the power of harmony and move into a more prosperous future.

Representative Director and President

Hiroshi Kokubun

About WAKOH Co., Ltd.

| Location |

2-15-9 Midori, Sumida City, Tokyo JAPAN 130-0021

> Google map |

|---|---|

| Phone | +81 3 3634 5645 |

| Business content | Apparel planning, sewing, retailing |

| Founding | 1929 |

| Capital | 19 million yen |

| Employee | 6 people |

About WAKOH KNIT IWATE Co., Ltd.

| Location |

80 Ooha Fujisawa Fujisawa-chou Ichinoseki-shi Iwate JAPAN

> Google map |

|---|---|

| Business content | Garment industry |

| Founding | 1968 |

| Capital | 10 million yen |

| Employee | 32 people |

Features of our Iwate sewing factory

Introduction of the latest machines

The P-CAM201S, the latest automatic high-speed cutting machine, and the NTS-200 sponging machine are introduced to handle high-mix, high-difficulty, small-lot items. Aiming for further efficiency, accurate and smooth cutting is being performed.

Production line organization for a wide range of items

We organize the most suitable sewing team for each product number. We handle many special sewing machines, mainly overlock/serge and lock stitch, to meet our customer's diversifying needs.

Double-check inspections are performed

Fabric defects and sewing problems are meticulously checked at each cutting, sewing, finishing, and inspection process. (Needle detection is carried out using the ND-398A needle detector.)

Equipment List

- Lockstitch Machine

- Sergers and Overlock sewing Machines

- Twin needle sewing machine

- Triple needle sewing machine

- Lockstitch sewing machine with two needles

- Vertical feed sewing machines

- Blind over edging sawing machine

- Zigzag stitch sewing machine

- Binder sewing machine

- Basting machines

- Blind hem sewing machine

- Mellow thin lock sewing machine

- Softseam sewing machine

- Straight buttonholing machine

- Button Sewing Machine

- Bartucking machine

- Heat press machine for interlining

- Spreading equipment

- Sponging machine

- CAD

- Automatic High-Speed Cutting Machine

- Band knife machine

- Ironing machine

- Needle Detector

Energy

From July 2023, we have switched the electricity used at our factories (Fujisawa-cho, Ichinoseki City, Iwate Prefecture) to electricity from renewable energy sources (solar, wind, geothermal, hydroelectric, and biomass) through UPDATER Corporation (formerly Minna Denryoku Co., Ltd.).

Our original brand, "WASHI-TECH", WASHI create, wear the future.

WASHI-TECH is a brand developed by a sewing factory, proposing clothes made of 100% Japanese traditional paper "Washi", which is a sustainable material with less environmental impact. Do you know Japanese traditional paper 'Washi"?

It has a history of 1,400 years. Washi is a natural high-tech material that has humidity control, antibacterial and deodorizing properties. Despite being made of paper, it can be washed over and over again. Smooth to the touch, crisp, and robust.

02WHY US

Making clothes that pursue the "comfort" of the wearer

Based on our 90-year history and reliable sewing technology, we provide valuable products that are always in demand by our customers.

Broad range of support

Broad range of support

From material proposal to delivery, we can provide one-stop production.

Example of secondary processing

- Silk Screen Printing

- Inkjet Printing

- Sublimation Transfer Printing

- Thermocompression Printing

- Greige Printing

- Embroidery

- Product Dyeing

- Patch

Our own factory

Our own factory

In addition to our own factory in Ichinoseki, Iwate Prefecture, we also carry out all of our partner factories and secondary processing in Japan.

- Monthly production of T-shirts

- Approx. 12,000 pieces

- Number of factory staff 32 members

- Installed an automatic high-speed cutting machine P-CAM201S

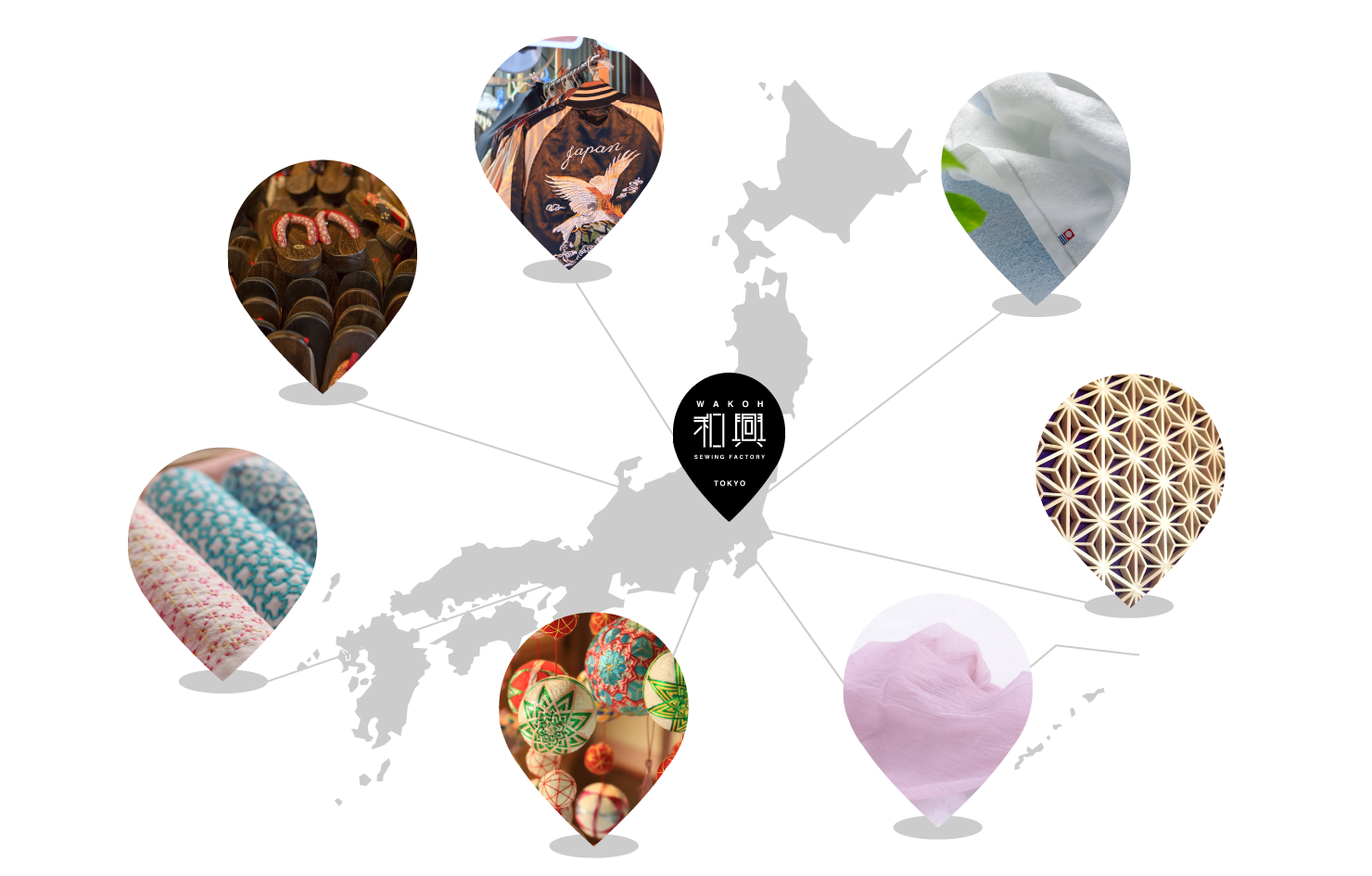

Nationwide Network

WAKOH has two bases, the Tokyo head office and the Iwate sewing factory, and partners specializing in various fields all over Japan. We will fulfill our customers' requests with traditional and state-of-the-art Japanese technologies. First, please let us know all your requests.

Smooth communication

Smooth communication

Staff with comprehensive skills of all aspects such as material procurement, planning, production management, and delivery will be in charge.

- Courteous communication

- Meetings are available at the Tokyo head office.

- A wide range of proposals to suit your needs

Aiming to produce the optimum quantity

Aiming to produce the optimum quantity

At our factory, we do not produce unnecessary large quantities.

Our optimum production system as well as planning and problem-solving skills, nurtured through relationships with many apparel companies and start-up brands, match today's society, which demands diversity.

Instead of creating products that are discarded without being worn. we aim to create products that are friendly to the earth and human.

Stable Infrastructure and logistic system

Japan's extremely stable infrastructure and logistics system allow us to produce the correct number of products at the right time. The climate is also stable, allowing us to focus on manufacturing with peace of mind.

Ensure traceability

Ensure traceability

We aim to make every step of the supply chain traceable, from raw material procurement to manufacturing, processing, and distribution, so that you can see the faces of our product manufacturers.

Manufacturing to meet the collection schedule

If you have a specific collection to attend, please let us know so we would do as much scheduling as possible.

03Service

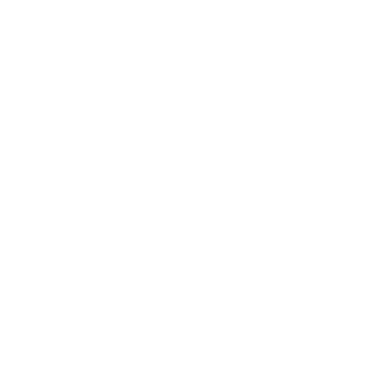

Main items that can be produced

Main services that can be provided

- Proposal of Design

- Proposal of Fabric

- Proposal of sub-materials

- Proposal of sewing specifications

- Proposal of Paper Hang Tag

- Brand name production

- Care label production

- Creation of specification sheets

- Pattern making

- Sample production

- Grading

- Ordering Materials

- Various printings

- Embroidery

- Garment dye

- Cutting

- Sewing

- Finishing

- Needle detection,Product Inspection

- Delivery to the designated destination

- Colour fastness test

- Material inventory management

Minimum Order Quantity

The minimum order quantity is the amount that can be taken from 1 fabric roll. We will first propose a production method that minimizes inventory, which is a concern for start-ups.

*Please note that the production quantity may vary slightly depending on the type of fabric roll.

| Item | Lot | Item | Lot |

|---|---|---|---|

|

T-shirts

|

30 pieces ~ |

Polo Shirts

|

30 pieces ~ |

|

Polo Shirts

|

30 pieces ~ | ||

|

Camisoles

|

30 pieces ~ |

Zip Hoodies

|

20pieces~ |

|

Zip Hoodies

|

20pieces~ | ||

|

One-piece Dresses

|

20pieces~ |

Knit Jacket

|

20pieces~ |

|

Knit Jacket

|

20pieces~ |

Please contact us for the items not listed above or for more information.

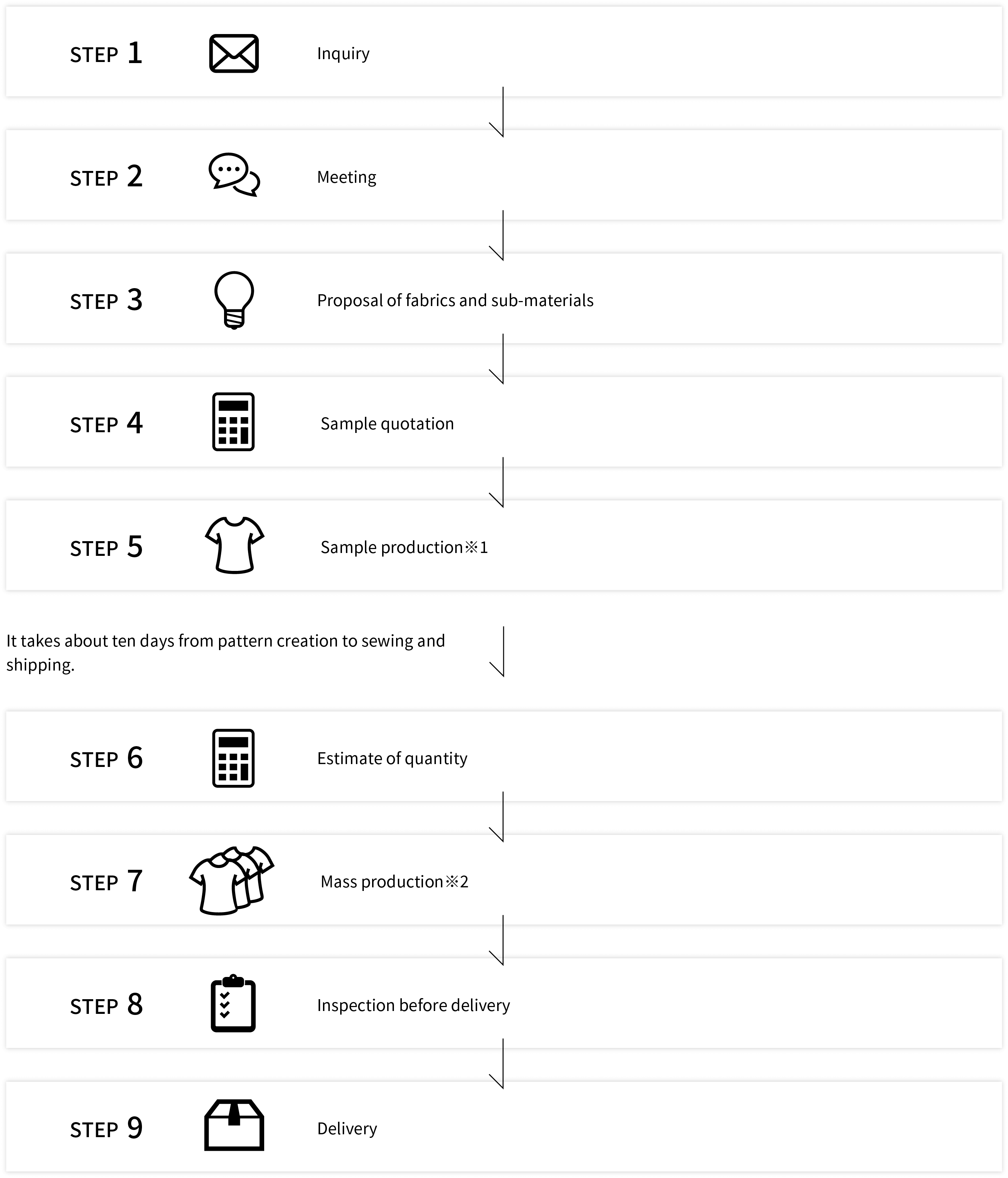

04order flow

Your payment needs to be made in advance. Please get in touch with us for further details.

For more detailed information on the delivery process, please visit our website. (Link to the Japanese site)

Please also see our Frequently Asked Questions.

05price

These are all reference prices; please inquire separately for details.

Prices are converted at 150 yen for 1 dollar.

| Item | Price |

|---|---|

|

T-shirts

|

$100.00~ USD |

|

Polo Shirts

|

$120.00~ USD |

|

Camisoles

|

$100.00~ USD |

|

Zip Hoodies

|

$133.33~ USD |

|

One-piece Dresses

|

$133.33~ USD |

|

Knit Jacket

|

$186.66~ USD |

*Price may vary depending on material and design.

*Please note that the above prices are for one sample, and separate charges will be incurred for the second and subsequent samples.

*Please consult us separately for sweaters and woven items.

| Item | Price |

|---|---|

|

T-shirts

|

$80.00~ USD |

|

Polo Shirts

|

$100.00~ USD |

|

Camisoles

|

$80.00~ USD |

|

Zip Hoodies

|

$133.33~ USD |

|

One-piece Dresses

|

$100.00~ USD |

|

Knit Jacket

|

$153.33~ USD |

*Price may vary depending on material and design.

*We do not deliver pattern data only.

| Item | Price |

|---|---|

|

T-shirts

|

$20.00~ USD |

|

Polo Shirts

|

$23.33~ USD |

|

Camisoles

|

$18.66~ USD |

|

Zip Hoodies

|

$37.33~ USD |

|

One-piece Dresses

|

$40.00~ USD |

|

Knit Jacket

|

$56.66~ USD |

*Price may vary depending on material and design.

*The above prices are reference prices for minimum lots.

*Please consult us separately for sweaters and woven items.

with Japan quality techniques and spirit of hospitality.

A long-established sewing manufacturer founded in 1929 in Japan.

We will propose the best way to meet your needs.

06Projects

Guiness "Dyed in gradation with plant cacao and expressed brand logo with intricate embroidery."

We proposed sweatshirts and caps to be given away by lottery in the “Guinness St. Patrick's Day Campaign” to the world-renowned Guinness Company.

Our merchandise's logo is delicately expressed with a fine needle count, showcasing our meticulous craftsmanship. The color of the letters was changed by one tone to make them stand out elegantly, further enhancing the quality and appeal of the merchandise.

For the sweatshirts, we tried a cacao-dyed gradation. Customers were delighted with this dyed finish.

In addition, we provided a satisfactory product by combining the best Japanese technology, such as special Urake fabrics, patches, sewing techniques, and so on.

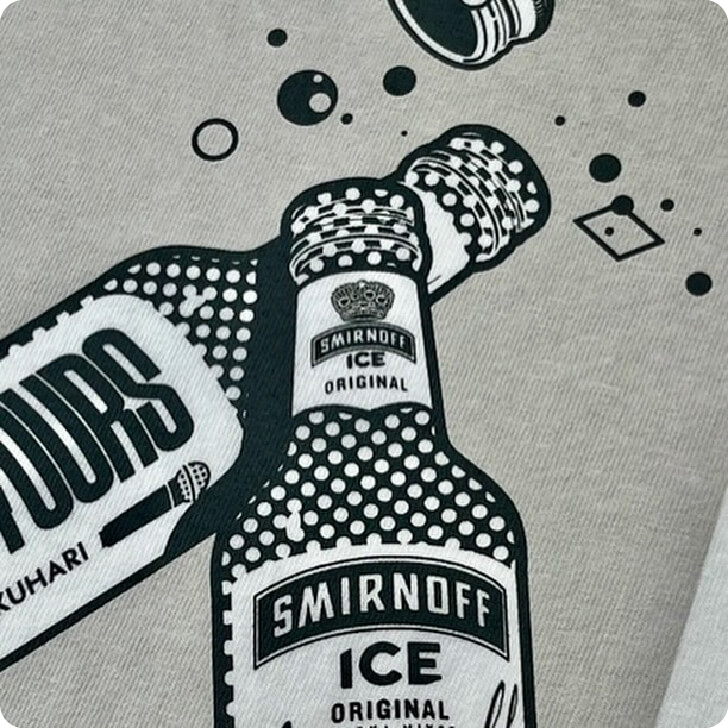

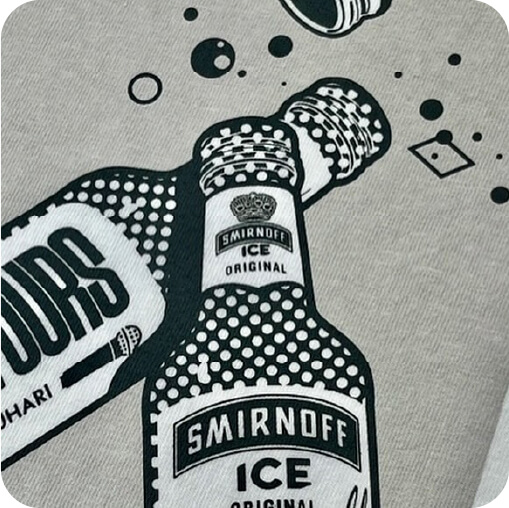

SMIRNOFF "We offered products comfortable to wear with silk screen printing that expresses less than 1mm. "

Multiple versions of silk printing with different mesh densities are used to represent the world-renowned Smirnoff graphics precisely. This technique is very advanced, with lines and die-cuts less than 1mm within a square of approximately 1cm of the crown logo.

In addition, the expression of subtle color differences, the fineness of the design, and its reproducibility dramatically increase the product's value.

The fabric used was a single jersey sinker fabric produced in Wakayama, and we proposed patternmaking with good texture and comfort.

https://www.smirnoff.com/en-gb

French brand's request, “ a vintage/used look with damage processing was expressed.”

We received a request from a customer, “We want to apply the damage processing often seen on jeans to T-shirts, and we proposed the technology of Kojima Jeans, a denim manufacturer that supplies denim to Maison brands. The customer was delighted with the finished T-shirt, which had well-calculated damage in a sophisticated manner.

Hidden five-toed socks knitted with washi yarn.

Although you can’t tell from the appearance, the inside is divided into five toes to stabilize the grip of the toes.

They are breathable and lightweight.

The original socks we provided also have excellent deodorizing and humidity control properties, and are difficult to tear and quick to dry.

A system to fulfill "I want realize what I have in mind"

Not sticking to only two bases, the Tokyo head office and the Iwate sewing factory, WAKOH can also offer a one-stop solution for manufacturing that takes advantage of traditional Japanese techniques and the unique characteristics of the production area. We also always look for the latest technological developments, kaizen, and sustainable manufacturing. We aim to be a hub that connects various technologies and production methods with the world.

07Customer Comments

Staff uniform (100% Japanese Washi paper) for Ksana, a matcha green tea cafe in Thailand

We met WAKOH at an exhibition in Thailand.

Our concept of wanting to be a reminder for people to appreciate nature and life matched the proposal of a uniform made of 100% washi paper, a sustainable material that has a low impact on the global environment.

The uniform graced the runway at Serbia Fashion Week.

Dressed in “washi” paper, which is a fusion of a long history and new technology, our staff would like to entertain customers with a sense of gratitude every day.

For those seeking peace of mind for a while, we set up Ksana Matcha to create a space that embodies “Escape from Chaos” and are working on it now.

Ksana matcha (Flagship Store) 2nd Floor, Unit R2-02, 548 Phloen Chit Rd, Lumphini, Pathum Wan, Bangkok, Thailand, Bangkok

URL:https://linktr.ee/ksana.bkk

Instagram:https://www.instagram.com/ksana.bkk

08[Declaration of Human Rights ~The Promise of WAKOH~]

- We prohibit discrimination of any kind, including race, ethnicity, creed, religion, gender, and national origin.

- We will strive to provide a safe, hygienic and healthy working environment.

- We will strive to ensure appropriate working hours and wages.

- We do not tolerate any form of harassment or any conduct that violates personal dignity.

- We do not tolerate child labor.

- We respect the diverse cultures and customs of all those with whom we interact.

- We will engage in corporate activities that are considerate of the global environment.

09FAQ

What kind of items can you manufacture?

We can handle all jersey-material items such as T-shirts, polo shirts, and hoodies. We can also manufacture miscellaneous goods and accessories other than apparel products. Please contact us for different projects, such as woven fabrics and sweaters.

I want to visit your factory.

It is possible. Our factory is in Ichinoseki, Iwate, Japan.

Please contact us in advance; we will be happy to show you around.

How many times can I ask for sample making?

You can do this as many times as you like. Samples can be made until you are satisfied.

*Please note that charges will be incurred for the second and subsequent samples.

Can I send in fabrics and materials?

It is possible. Please contact us for the shipping address each time.

Can I have an online meeting?

It is possible.

Please let us know our payment condition.

Your payment needs to be made in advance. Please get in touch with us for further details.

How long does it take for delivery?

Since the delivery time varies depending on the timing of production, please check each time.

Can I choose the shipping agent?

Yes, you can.

If your question is not resolved, please get in touch with us here.

with Japan quality techniques and spirit of hospitality.

A long-established sewing manufacturer founded in 1929 in Japan.

We will propose the best way to meet your needs.

10Contact information

Opening hours: 10:00 a.m. - 6:00 p.m. JST

We would be happy if WASHI-TECH uniforms made of 100% WASHI (Japanese paper) born in Japan could help workers and customers feel at ease at the Ksana's store, which also serves as a bridge between Japan and Thailand.